Dualtone Automotive 4745 Mission Bay Dr. San Diego, CA 92109 © Dualtone Automotive Inc. 2015

Serving San Diego Since 1946

The Parts That Hold It all Together

Suspension systems are made up of several components, all of which may benefit from a scheduled inspection even if your two-wheel or four-wheel drive vehicle is showing little sign of misalignment. A reliable system may produce an easy ride, but that is only half of its job. The other is to keep the vehicle stable and prevent it from losing its grip on the road. Parts to inspect include: • Sway bar or stabilizer bar • Inner and outer tie rod ends • Ball joints • Idler arm and pitman arm • Control arm bushings • Coil, leaf and air springs

Phone: (858) 273-874 (619) 276-4525

8:00am-500pm

8:00am-200pm

Closed

At Dualtone we can handle cars that don’t handle well

Several warning signs can tell you when shock absorbers need replacing,

such as your car bottoms out over railroad tracks, speed bumps or dips in the

road or keeps bouncing well after the fact. Other signs are unusual noises over

bumps, excessive body lean in turns or that the front end of the car dives

sharply in hard braking. Because shocks wear out gradually, you might get used

to a looser, bouncier ride, much like you get used to longer stopping distances

as brake pads wear out.

One way to test shocks is to push down hard on each corner of a vehicle.

If the car continues to bounce after you let go, your shocks need replacing.

However, this test may require quite a bit of strength, and with many high-riding

SUVs and pickups it isn't easy to get the leverage you need.

Instead, you should have a qualified mechanic check your shock

absorbers when your car is on a lift, such as when you have tires rotated. The

mechanic will be able to see if there are major leaks (shock absorbers are filled

with fluid), worn mounts or bushings, or physical damage such as dents.

When you need to replace your shocks or struts can vary by vehicle and how and where you drive. If you frequently

drive over rough, pockmarked roads that put more stress on the shock absorbers, then you will probably need to replace them

more often than if you drive mainly on smooth pavement. Carrying heavy loads also will wear out shocks faster.

When you begin to notice your car or truck bouncing or nose-diving when you brake, it is time to call us at Dualtone of

San Diego. We excel at getting the right shock absorber and strut replacement for your foreign or domestic vehicle. Even if

you are not bobbing on the road, small changes in handling may indicate it is time for a check.

Shocks and struts

At Dualtone of San Diego, we understand you want to enjoy a smooth ride and great drivability from your car or truck. A key

to getting the best experience is regular maintenance and suspension repair when you need it. In an annual checkup, we will

inspect, adjust and fix any issues with front and rear suspension that could compromise your driving safety and pleasure.

We Repair CV Joints and Drive Axles in San Diego

At Dualtone of San Diego, our goal is to help keep your foreign or domestic auto or pickup in factory condition for as long as you own it. Any sort of daily driving puts stress on a vehicle. Axles are designed for different needs, but in general they stabilize a vehicle under conditions of speed and weight. Over time, parts may need attention. If an inspection shows a weakness in the system, it may be time for a CV axle replacement. Dualtone services all types of vehicles, including: • Rear-wheel drive (RWD) • Four-wheel drive (4WD) • Front-wheel drive (FWD)How They Work

An axle shaft is a narrow piece, like a pole, that connects a wheel to the gears in the transmission of your car or truck. In most FWD cars, the drive axle is split between two half axles, with differential and universal joints, or u-joints, in between. The constant velocity (CV) joint is a third piece that allows the wheels to move freely. This joint enables the shaft to rotate, transmitting power at a constant speed without causing an excess of friction and heat. When a boot, or grease container, leaks and the CV joint fails to be properly lubricated, it may eventually wear out and require a shaft assembly replacement.When to See a Pro for a Proper Fix

Sometimes it is clear when something is off, other times it is harder to tell. The following are some of the signs that something is off kilter with the suspension: • The road feels rough and the ride is jerky • The front end nose-dives when the car brakes • The car seems to drift or pull during turns • The tire tread is uneven • The shocks appear oily, indicating a leak

control arm bushings

Bushings are commonly found at hinge points in the suspension. Most

are designed to allow rotational movement while limiting lateral or side to

side motion. This movement allows the suspension parts to move freely, for

example, when traveling over a large bump, while minimizing transmission of

noise and small vibrations through to the chassis of the vehicle. Like all

rubber components they are susceptible to wear and contamination from oil

and the elements. Worn bushings can lead to clunking noises as well as

wheel misalignment.

Ball Joints

ball joints are spherical bearings that connect the control arms to the

steering knuckles .In automobile suspension, the two ball joints are called the

"upper ball joint" and "lower ball joint". Lower ball joints are typically larger and

wear out faster as the entire front end weight rests upon them. Over time ball

joints wear their sockets to the point where the ball is no longer held securely.

This wear can lead to bump steer, a condition in which the the vehicle will

change direction after hitting a patch of uneven road without input from the

driver, as well as increased tire wear.

Idler arms, pitman arms and tie rod ends

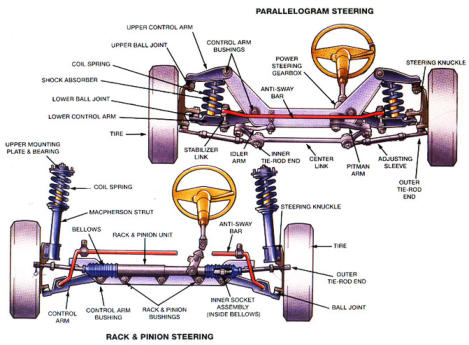

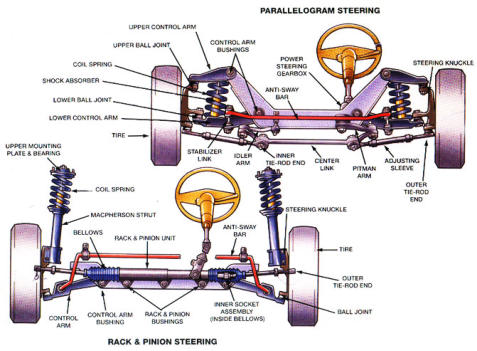

The two common types of steering systems in use

today are rack and pinion and parallelogram.

A parallelogram steering linkage is called such

because like its name sake the two sides of the linkage run

parallel to each other and are equal in distance. This type of

steering linkage uses four tie rods, one inner and one outer

on each side (left and right), a center link (which runs

between the tie rods), an idler arm on the passenger side,

and a pitman arm on the driver side. The pitman arm

attaches to the steering gear output shaft which is also

commonly called the pitman shaft. The pitman arm attaches

to the center link and is moved by turning the steering

wheel. The center link transfers the movement from the

pitman arm and pitman shaft to the idler arm on the

passenger side. The inner tie rods are mounted to the center

link and transfer steering motion to the steering arms and

outer tie rods. All of the joints which mount these

components are constructed of small ball and socket joints

to provide the necessary freedom of movement required to maintain control over the vehicle while it is in motion. The rack and

pinion system is simpler than the parallelogram design but it’s components have a similar design and therefore the common

weaknesses. Over time, the inner tie-rod ends wear and can cause excessive play in the steering linkage. Also, bellows boots

may become torn or dislodged from their seat. When bellows boots are torn, dirt or abrasives may enter the unit, accelerating

wear of rack-and-pinion seals and bushings. Routine inspection can identify damage early, before additional problems arise.

Dualtone Automotive 4745 Mission Bay Dr. San Diego, CA 92109 © Dualtone Automotive Inc. 2015

Serving San Diego Since 1946

The Parts That Hold It all Together

Suspension systems are made up of several components, all of which may benefit from a scheduled inspection even if your two-wheel or four-wheel drive vehicle is showing little sign of misalignment. A reliable system may produce an easy ride, but that is only half of its job. The other is to keep the vehicle stable and prevent it from losing its grip on the road. Parts to inspect include: • Sway bar or stabilizer bar • Inner and outer tie rod ends • Ball joints • Idler arm and pitman arm • Control arm bushings • Coil, leaf and air springsWe Repair CV Joints and Drive Axles in

San Diego

At Dualtone of San Diego, our goal is to help keep your foreign or domestic auto or pickup in factory condition for as long as you own it. Any sort of daily driving puts stress on a vehicle. Axles are designed for different needs, but in general they stabilize a vehicle under conditions of speed and weight. Over time, parts may need attention. If an inspection shows a weakness in the system, it may be time for a CV axle replacement. Dualtone services all types of vehicles, including: • Rear-wheel drive (RWD) • Four-wheel drive (4WD) • Front-wheel drive (FWD)How They Work

An axle shaft is a narrow piece, like a pole, that connects a wheel to the gears in the transmission of your car or truck. In most FWD cars, the drive axle is split between two half axles, with differential and universal joints, or u-joints, in between. The constant velocity (CV) joint is a third piece that allows the wheels to move freely. This joint enables the shaft to rotate, transmitting power at a constant speed without causing an excess of friction and heat. When a boot, or grease container, leaks and the CV joint fails to be properly lubricated, it may eventually wear out and require a shaft assembly replacement.

At Dualtone we can handle

cars that don’t handle well

At Dualtone of San Diego, we understand you want to

enjoy a smooth ride and great drivability from your car or truck.

A key to getting the best experience is regular maintenance

and suspension repair when you need it. In an annual

checkup, we will inspect, adjust and fix any issues with front

and rear suspension that could compromise your driving safety

and pleasure.

When to See a Pro for a Proper Fix

Sometimes it is clear when something is off, other times it is harder to tell. The following are some of the signs that something is off kilter with the suspension: • The road feels rough and the ride is jerky • The front end nose-dives when the car brakes • The car seems to drift or pull during turns • The tire tread is uneven • The shocks appear oily, indicating a leakShocks and struts

Several warning signs can tell you when shock absorbers

need replacing, such as your car bottoms out over railroad

tracks, speed bumps or dips in the road or keeps bouncing

well after the fact. Other signs are unusual noises over bumps,

excessive body lean in turns or that the front end of the car

dives sharply in hard braking. Because shocks wear out

gradually, you might get used to a looser, bouncier ride, much

like you get used to longer stopping distances as brake pads

wear out.

One way to test shocks is to push down hard on each

corner of a vehicle. If the car continues to bounce after you let

go, your shocks need replacing. However, this test may require

quite a bit of strength, and with many high-riding SUVs and

pickups it isn't easy to get the leverage you need.

Instead, you should have a qualified mechanic check

your shock absorbers when your car is on a lift, such as when

you have tires rotated. The mechanic will be able to see if

there are major leaks (shock absorbers are filled with fluid),

worn mounts or bushings, or physical damage such as dents.

When you need to replace your shocks or struts can vary

by vehicle and how and where you drive. If you frequently drive

over rough, pockmarked roads that put more stress on the

shock absorbers, then you will probably need to replace them

more often than if you drive mainly on smooth pavement.

Carrying heavy loads also will wear out shocks faster.

When you begin to notice your car or truck bouncing or

nose-diving when you brake, it is time to call us at Dualtone of

San Diego. We excel at getting the right shock absorber and

strut replacement for your foreign or domestic vehicle. Even if

you are not bobbing on the road, small changes in handling

may indicate it is time for a check.

control arm bushings

Bushings are commonly found at hinge points in the

suspension. Most are designed to allow rotational movement

while limiting lateral or side to side motion. This movement

allows the suspension parts to move freely, for example, when

traveling over a large bump, while minimizing transmission of

noise and small vibrations through to the chassis of the vehicle.

Like all rubber components they are susceptible to wear and

contamination from oil and the elements. Worn bushings can

lead to clunking noises as well as wheel misalignment.

Ball Joints

ball joints are spherical bearings that connect the control

arms to the steering knuckles .In automobile suspension, the two

ball joints are called the "upper ball joint" and "lower ball joint".

Lower ball joints are typically larger and wear out faster as the

entire front end weight rests upon them. Over time ball joints

wear their sockets to the point where the ball is no longer held

securely. This wear can lead to bump steer, a condition in which

the the vehicle will change direction after hitting a patch of

uneven road without input from the driver, as well as increased

tire wear.

Idler arms, pitman arms and tie rod ends

The two common types of steering systems in use today are

rack and pinion and parallelogram.

A parallelogram steering linkage is called such because like

its name sake the two sides of the linkage run parallel to each

other and are equal in distance. This type of steering linkage uses

four tie rods, one inner and one outer on each side (left and right),

a center link (which runs between the tie rods), an idler arm on

the passenger side, and a pitman arm on the driver side. The

pitman arm attaches to the steering gear output shaft which is

also commonly called the pitman shaft. The pitman arm attaches

to the center link and is moved by turning the steering wheel. The

center link transfers the movement from the pitman arm and

pitman shaft to the idler arm on the passenger side. The inner tie

rods are mounted to the center link and transfer steering motion

to the steering arms and outer tie rods. All of the joints which

mount these components are constructed of small ball and socket

joints to provide the necessary freedom of movement required to

maintain control over the vehicle while it is in motion. The rack

and pinion system is simpler than the parallelogram design but it’s

components have a similar design and therefore the common

weaknesses. Over time, the inner tie-rod ends wear and can

cause excessive play in the steering linkage. Also, bellows boots

may become torn or dislodged from their seat. When bellows

boots are torn, dirt or abrasives may enter the unit, accelerating

wear of rack-and-pinion seals and bushings. Routine inspection

can identify damage early, before additional problems arise.